Why Logistics Is the New Marketing Lever

When shop owners think about Shopware fulfillment, they usually picture this: A package gets packed, a label printed, and the DHL courier picks it up. But in 2025, this definition no longer suffices. In an e-commerce market where customer acquisition costs (CAC) are rising and margins are under pressure from inflation and logistics fees, fulfillment is no longer just a cost center—it's a decisive competitive factor.

Most merchants optimize their logistics for speed: Same Day Delivery and late cut-off times are the standard. But there's a massive problem that often gets ignored in classic logistics discussions: The return. What good is the fastest shipping if 30% to 50% of packages come back? This is where the real leverage lies for Shopware merchants.

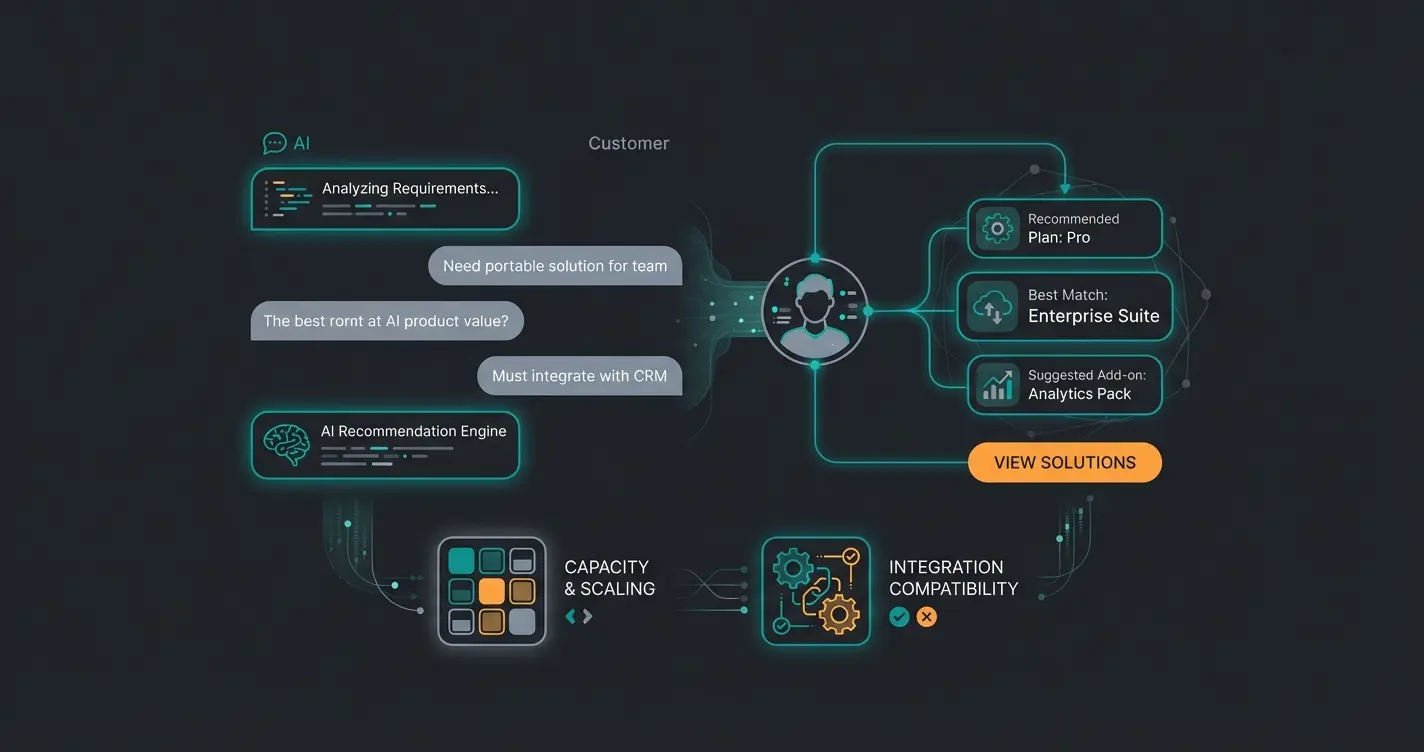

This guide takes you not only through the technical fundamentals of warehouse logistics in Shopware 6 but shows you an entirely new perspective: Customer Satisfaction Fulfillment. We'll demonstrate how the use of AI and strategic pre-purchase consultation (Pre-Fulfillment) relieves your logistics chain before the order is even placed. Understanding how AI-powered product consultation impacts fulfillment efficiency is crucial for modern e-commerce success.

The 3 Pillars of Modern Shopware Fulfillment

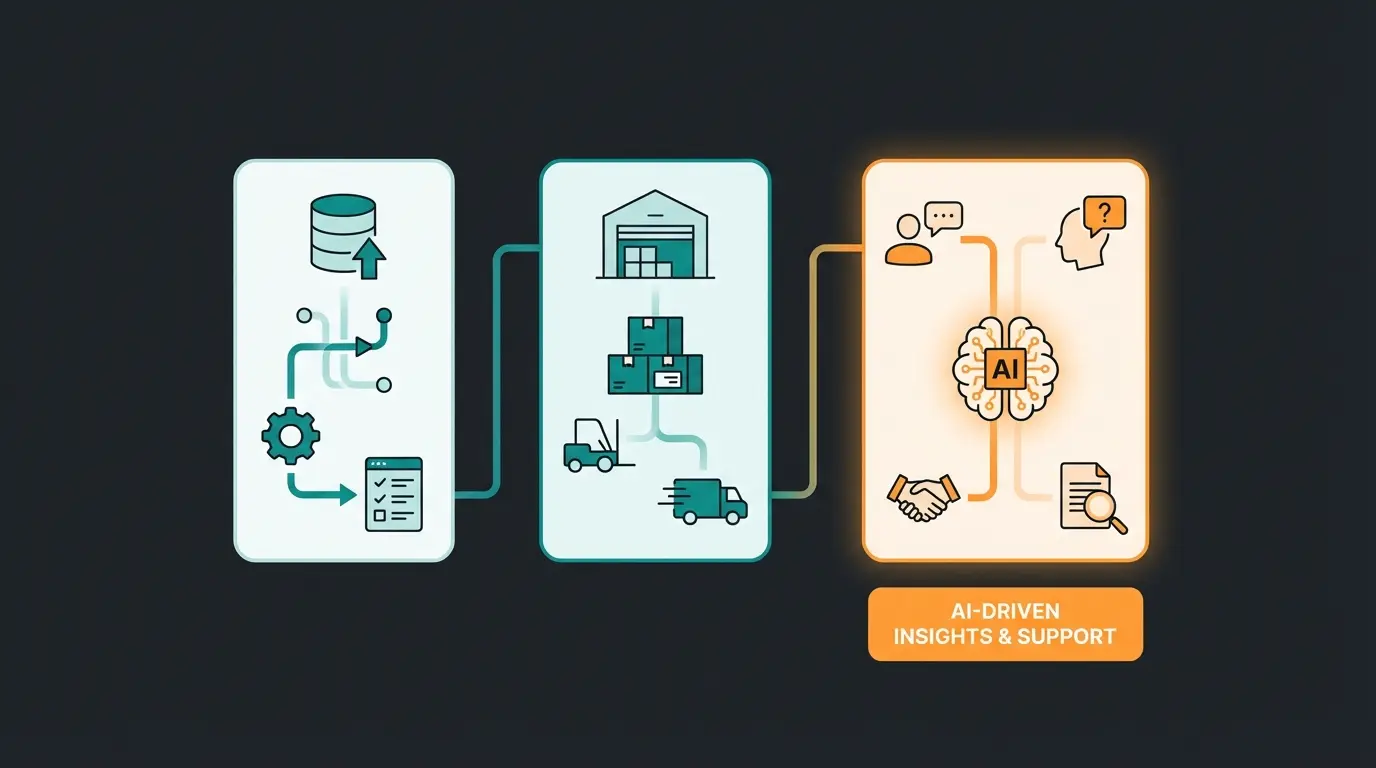

To view this topic holistically, we need to divide fulfillment into three pillars. Most agencies and 3PL providers only discuss the first two. However, the third pillar is the one that will determine your profitability in 2025.

Pillar 1: Digital Order Processing

Before a physical product moves, data must flow. Shopware 6 provides an excellent foundation for this. The heart of everything is your ERP & merchandise management system. Whether you use Pickware (directly integrated into Shopware) or external giants like JTL, Xentral, or SAP—real-time inventory synchronization is mandatory.

According to Shopware, the Shopware Flow Builder is a powerful tool for automation. Instead of manually reviewing orders, you define flows: If order paid -> Then send data to warehouse -> Then print delivery note. The connection between your shop and warehouse (whether your own warehouse or service provider) happens through interfaces (API), as detailed in Solution25's documentation.

Pillar 2: Physical Logistics

This is where the actual work on the product happens. Warehousing covers storage and shelving systems (chaotic vs. static). Pick & Pack involves assembling the order and packaging it. Shipping means handover to carriers like DHL, UPS, or Hermes. And Returns Handling encompasses receiving, inspecting, and refurbishing returns.

Pillar 3: The Pre-Fulfillment Strategy (The Game Changer)

This is the gap in almost every strategy. Fulfillment begins in the customer's mind. The problem: Customers often order items to try on or select wrong variants because they're uncertain. This leads to enormous strain on Pillar 2.

The solution: AI-powered product consultation. When an AI (like an intelligent purchase advisor in chat) guides the customer to the right size or matching technical accessory before they click Buy, the return becomes unnecessary. Discover how AI employees revolutionize this approach to customer service.

The effect: You save not only shipping costs (both ways) but also processing costs in the warehouse (receiving, inspection, repackaging). This is where the real optimization potential lies—not in negotiating slightly better carrier rates.

Searching for a bike part or jeans with uncertainty about fit or compatibility

Guided selling tool or chatbot analyzes questions and guides through product selection

Customer orders only the product that actually fits their needs

Warehouse only needs to pick one item instead of multiple variants

Customer is satisfied, margin stays intact, logistics costs minimized

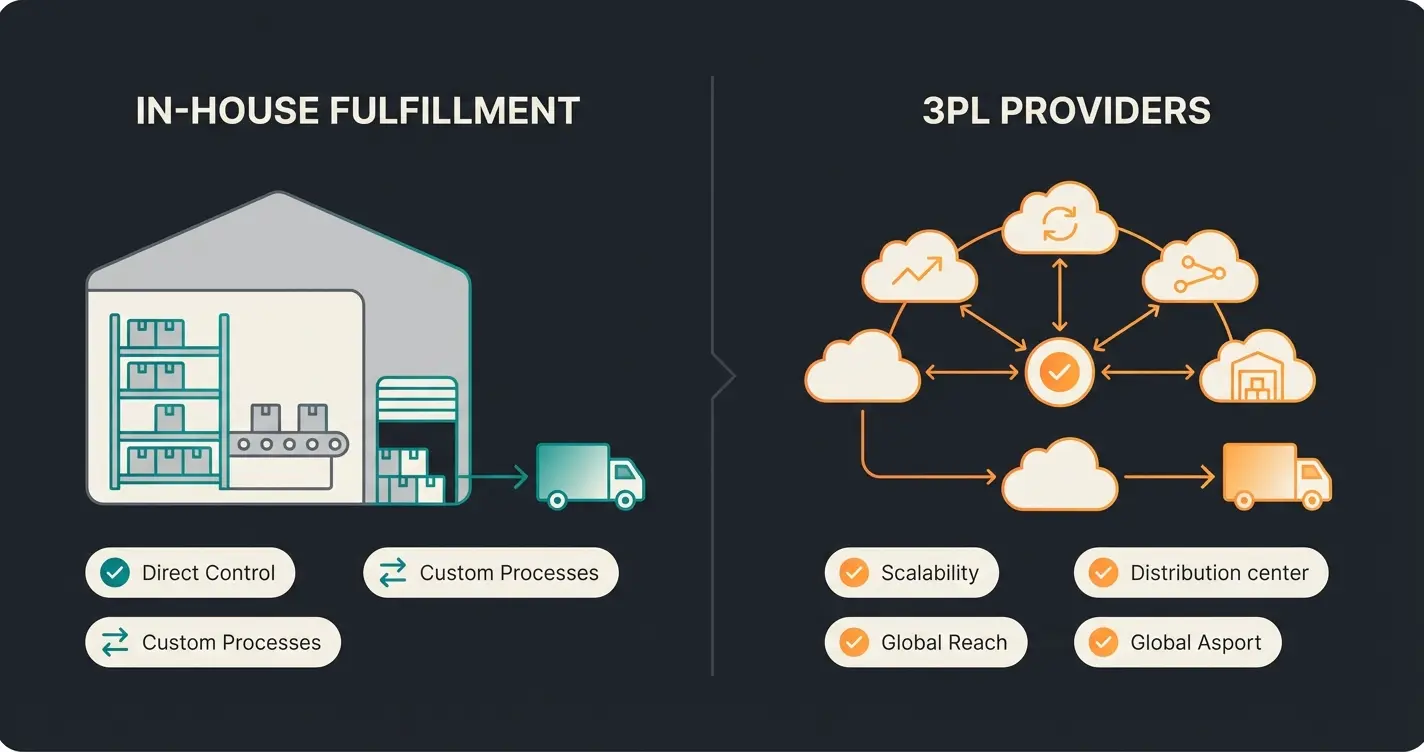

In-House vs. Outsourced Fulfillment: The Eternal Question

One of the first decisions you must make as a Shopware merchant: Do you handle it yourself (In-House) or outsource it (Outsourcing/3PL)? Both paths have their justification, depending on your phase and business model.

In-House Fulfillment (Self-Processing)

Here you retain full control. For Shopware users, Pickware is often the first choice since it runs as a native ERP/WMS directly in the Shopware backend, as explained on Pickware's platform.

- Full control over the unboxing experience (inserts, special wrapping paper)

- Fast reaction times when problems arise

- No dependency on external service providers

- Data sovereignty: Everything stays in your Shopware system

However, there are significant disadvantages: High fixed costs (rent, personnel, shelving, scanners), difficult scaling during seasonal peaks (e.g., Black Friday), and you bear the full risk for staff shortages.

Outsourced Fulfillment (3PL - Third Party Logistics)

You hand over your goods to professionals like byrd, Quivo, or Warehousing1. Your Shopware shop sends the order via API, and the service provider handles the rest.

- Variable costs: You usually only pay per storage slot and per pick (Pay-as-you-go)

- Massive scalability: If you have 10,000 orders tomorrow, that's the provider's problem

- Access to cheaper shipping rates through bundled volumes

The disadvantages include less control over the physical process, potentially complex IT integration (if no plug & play solution exists), and often opaque hidden costs (see Section 5). This is where AI-powered consultation can help reduce the return burden regardless of your fulfillment model.

| Feature | In-House (e.g., with Pickware) | Outsourced (3PL Provider) |

|---|---|---|

| Control | Very high (100%) | Medium (standard processes) |

| Fixed Costs | High (warehouse, personnel) | Low (usually transaction-based) |

| Scalability | Limited (by own space/personnel) | Very high |

| Shopware Integration | Native (directly in backend) | Via Plugin/API (sync required) |

| Returns Handling | Manual in own warehouse | Automated, but often expensive |

| Impact of Returns | Ties up own personnel significantly | Costs money per transaction |

| Ideal for... | Niche products, high customization, startups | Strong growth, standard goods, internationalization |

Top Shopware Fulfillment Providers in Germany (2025)

The market for fulfillment service providers in Germany is huge. Based on current market data from E-Commerce Germany and Clutch, along with Shopware compatibility assessed by SourceForge, these are the most relevant players for 2025.

1. DHL Fulfillment

The classic choice. Specialty: Unbeatable network in Germany. Shopware Integration: Very good through official adapters. Best for: Merchants who want to generate maximum trust with end customers through the DHL brand. Their AI optimization strategies can further enhance the integration.

2. byrd

A tech logistics company with a strong European network. Specialty: Cloud-based platform giving you access to warehouses across Europe. Ideal for cross-border commerce. Shopware Integration: Offers a Plug & Play plugin for Shopware 6. Best for: Scaling brands with international focus.

3. Quivo (formerly various brands)

Focused on transparency and modern dashboards. Specialty: Strong focus on customer experience and easy connection. Shopware Integration: Available. Best for: D2C brands (Direct-to-Consumer) that value a modern interface.

4. Warehousing1

Not a classic logistics company, but a network/aggregator. Specialty: Matches you with the right logistics provider from their network while offering a central software interface. Shopware Integration: Central interface. Best for: Merchants seeking flexibility who don't want to be tied to a single location.

5. Pickware (The In-House Solution)

As mentioned, not a 3PL but the software to do it yourself. Specialty: WMS and ERP directly in Shopware. Barcode scanner app for iOS as noted on Shopware's store. Best for: Merchants who want to operate their own warehouse and use Shopware. Consider how AI consultation boosts can complement your in-house operations.

How to Reduce Fulfillment Costs (The Secret Method)

Let's get to the strategic core of this article. If you google how to reduce fulfillment costs, you usually read tips like: Negotiate better DHL prices or Use lighter boxes. That's not wrong, but it's small change compared to the elephant in the room: The return.

The Real Calculation: Total Cost of Fulfillment

Many merchants calculate their fulfillment costs incorrectly. They only see the costs for outbound shipping. But a return costs on average between €5 and €10 (handling + value loss), in complex cases up to €20. According to Qualimero's research and FashionUnited, these hidden costs devastate margins.

Here's a realistic calculation showing why Pre-Fulfillment (prevention) is so powerful:

| Cost Factor | Traditional View (Shipping Only) | Smart View (With Return Risk) | With AI Consultation (Optimized) |

|---|---|---|---|

| Pick & Pack | €1.50 | €1.50 | €1.50 |

| Shipping (Outbound) | €4.90 | €4.90 | €4.90 |

| Return Rate | - | 20% (Fashion/Tech Average) | 14% (Reduced through AI) |

| Cost per Return | - | €8.00 (Shipping + Handling) | €8.00 |

| Calculated Return Costs per Order | €0.00 | €1.60 (20% of €8) | €1.12 |

| TOTAL Cost per Order | €6.40 | €8.00 | €7.52 |

Result: By lowering the return rate by just 6 percentage points (from 20% to 14%), you save almost €0.50 per order in pure margin. With 10,000 orders per month, that's €5,000 in net profit—without selling a single additional package.

Studies show AI consultation can reduce returns significantly

Average handling and shipping costs for each returned item

Margin improvement through 6% return rate reduction

Potential yearly savings for 10,000 monthly orders

Understanding the Customer Journey Gap

How do you achieve this reduction? By defining fulfillment not as logistics, but as customer satisfaction. The customer arrives searching for a bike spare part or jeans. The uncertainty hits: Does this part fit my 2020 model? Does size M run small? This is where returns normally originate (or orders for two sizes to choose from).

The AI intervention (Pre-Fulfillment) changes everything. Instead of letting the customer guess, an AI steps in (e.g., a guided selling tool or chatbot). It analyzes the question or guides the customer through a questionnaire (What model do you ride?). The result: The customer orders only the product that truly fits. Learn more about how AI Product Consultation providers are transforming this space.

Case Study Evidence: Studies from GodOfPrompt and US Chamber of Commerce show that personalized recommendations and AI-powered size consulting can significantly reduce return rates—sometimes by up to 30-35%.

Discover how AI-powered product consultation can reduce your return rate by up to 30% and save thousands in fulfillment costs every month.

Start Free TrialTechnical Integration in Shopware 6

How do you implement this strategy technically? Shopware 6 is predestined for this thanks to its API-first architecture.

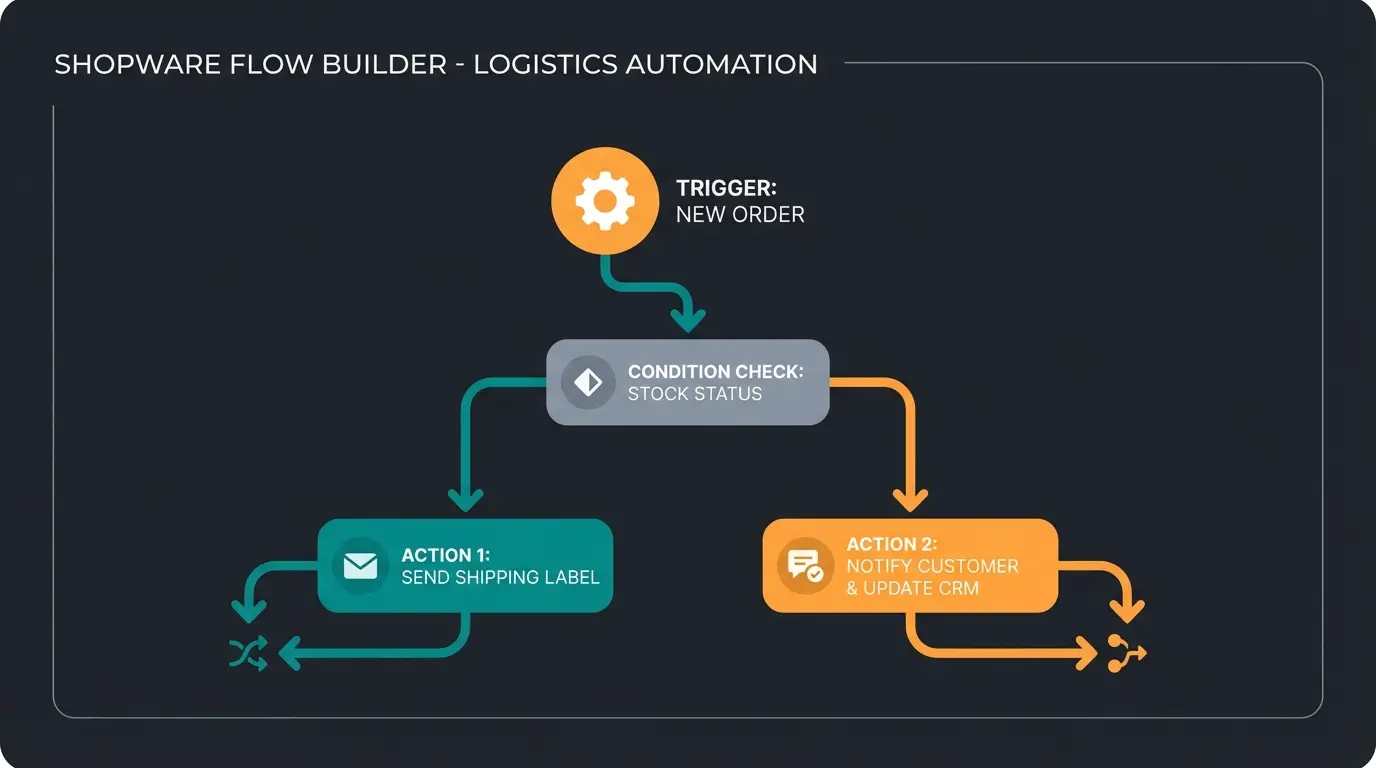

The Shopware Flow Builder as Your Logistics Brain

The Flow Builder is your most important tool for automation, as documented on Shopware's official site. It allows you to control logistics processes without programming knowledge.

Example Flow for Logistics Automation:

- Trigger: `checkout.order.placed` (Order placed)

- Condition: `shipping_method` is Express AND `payment_status` is Paid

- Action 1: Send email to warehouse Priority: High

- Action 2: Tag order in admin with Express

- Action 3: Trigger webhook to 3PL provider (for immediate pick)

Integration of AI Tools (Pre-Fulfillment)

To integrate return prevention, you need to work upstream—in the frontend. There are various plugins for size advisors or guided selling in the Shopware Store, as listed on Shopware's extension marketplace. Implementing AI-driven consultation alongside your product pages creates powerful cross-selling opportunities.

Shopware itself offers AI Copilot functions to improve product descriptions (which reduces misunderstandings and thus returns), according to Steireif and Shopware's AI documentation. Through the API, you can connect external AI chatbots that have access to your product data and actively advise customers. AI-powered sales consultants represent the cutting edge of this technology.

Returns Portal Management

For cases where a return does happen (which can never be 100% avoided), Shopware offers native returns management starting with the Rise version, as shown on Shopware and demonstrated on YouTube. Customers can register returns in their customer account, and you can generate labels automatically (e.g., via DHL Adapter).

For the Community Edition (CE), you need third-party plugins (e.g., Pickware or DHL Adapter) to retrofit this functionality, as detailed on Qualimero. Understanding how AI consultants boost cart completion rates also reduces the need for returns from mistaken purchases.

Building Your Pre-Fulfillment Strategy

The most profitable fulfillment strategy is the return that never happens. This requires thinking beyond traditional logistics optimization. When you implement AI-powered product consultation, you're not just improving customer service—you're fundamentally changing your cost structure.

Consider the impact on your entire operation. Your warehouse team spends less time processing returns. Your customer service handles fewer complaints about wrong products. Your inventory management becomes more predictable when fewer items cycle back through the system. This is the power of addressing problems at their source.

The integration of KI E-Commerce solutions into your Shopware store creates a virtuous cycle. Better consultation leads to fewer returns, which lowers costs and improves customer satisfaction, which drives repeat purchases. This is the fulfillment flywheel in action.

Advanced Optimization with Structured Data

Beyond the core fulfillment strategy, consider how your product information architecture affects returns. Poor product data leads to customer confusion, which leads to wrong purchases. An AI consulting guide can help you optimize your product information for both search engines and customer clarity.

When your product pages clearly communicate specifications, compatibility information, and sizing details—enhanced by AI-powered Q&A—customers make better decisions. This upstream optimization complements your fulfillment strategy perfectly. Learn more about comprehensive AI product consultation approaches in our detailed guide.

Conclusion: The Future of Shopware Fulfillment

The market for Shopware fulfillment is transforming. In 2025, it's no longer enough to just move packages from A to B. Logistics costs are rising, and customers expect free shipping and returns—a toxic combination for your margin.

Tomorrow's winners will be those who expand their fulfillment strategy across two dimensions:

- Efficient Processing: Through automation with the Flow Builder and seamless integration (Pickware or 3PL)

- Intelligent Prevention: Through the use of AI in the consultation phase to prevent the most expensive of all logistics movements—the return

Action Recommendations

- Analyze your return rate. If it's above 15%, you don't have a logistics problem—you have a consultation problem

- Check whether your current fulfillment setup (In-House vs. 3PL) still fits your volume

- Use the Shopware Flow Builder to eliminate manual processes in the warehouse

- Implement AI-powered product consultation to reduce returns at the source

Fulfillment is no longer just the end of the chain (shipping goods). It's a cycle that begins at the first customer interaction. Optimize this cycle, and you optimize your profit.

FAQ: Common Questions About Shopware Fulfillment

Costs vary significantly. With 3PL providers, you typically pay a pick fee (approx. €1.50 - €2.50) plus storage fees per cubic meter/pallet and shipping costs. In-house operations incur fixed costs for rent and personnel, but variable costs per package are lower.

Yes, there are plugins (e.g., from Magnalister or Brickfox) that connect Shopware with Amazon FBA. This is called Multi-Channel Fulfillment and allows you to leverage Amazon's logistics infrastructure for Shopware orders.

For native integration, Pickware WMS is the market leader. For larger, complex warehouse structures, many merchants use JTL-Wawi or Xentral, which connect via interface. The choice depends on your warehouse complexity and order volume.

AI analyzes customer data and product data to provide precise size recommendations (e.g., customers like you bought size L) or answers specific questions about product compatibility in chat before the purchase is made. This prevents wrong orders at the source.

Industry benchmarks suggest aiming for under 15% in most categories. Fashion typically runs higher (20-30%), while electronics and home goods can achieve under 10%. With AI consultation, many merchants reduce their rates by 6-10 percentage points.

Join leading Shopware merchants using AI consultation to reduce returns, cut costs, and boost customer satisfaction. See results in weeks, not months.

Get Started Free